1How does a battery monitoring system work?

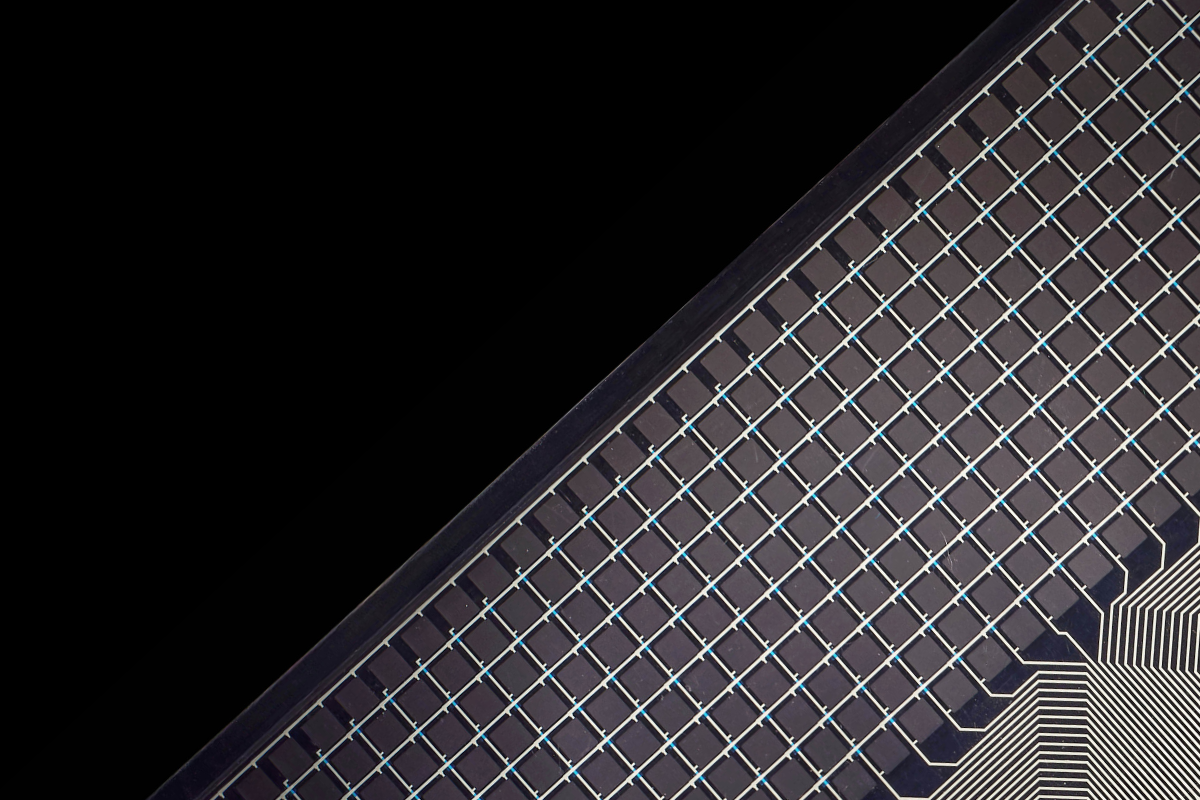

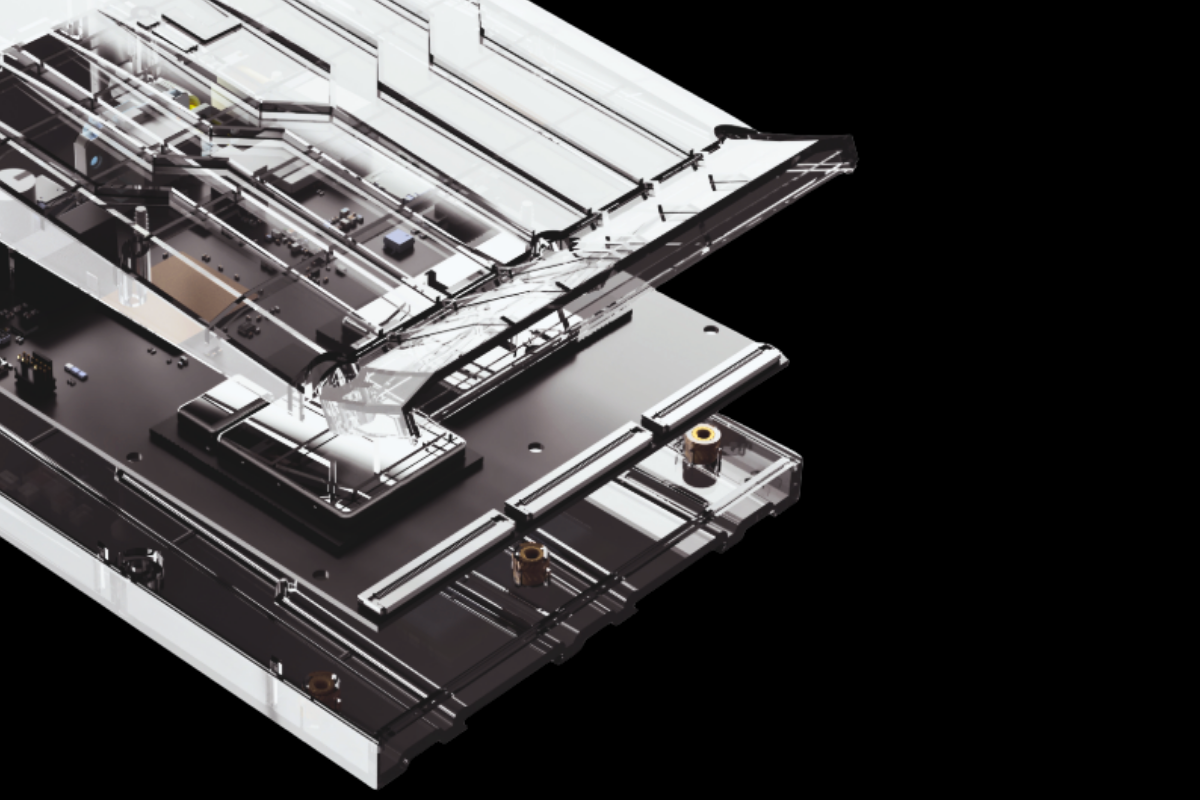

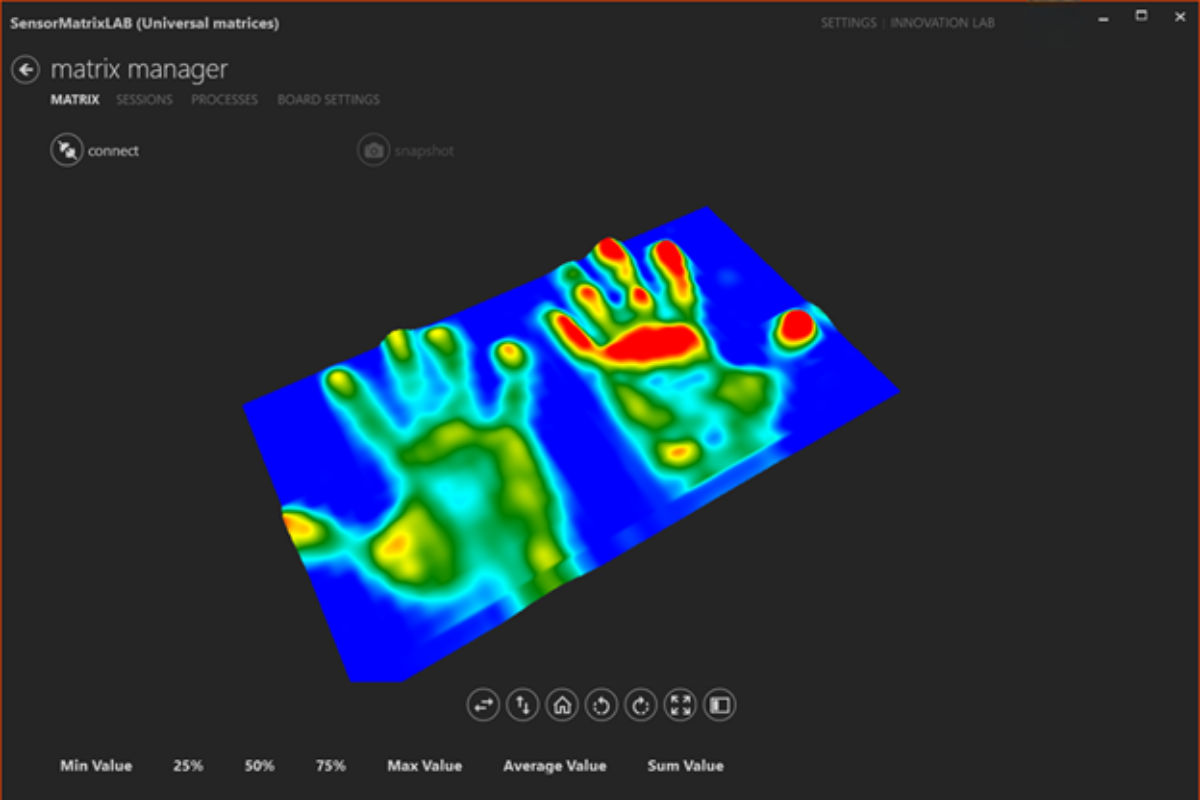

BaMoS utilizes ultra-thin printed sensors strategically positioned around and between battery cells to monitor pressure and temperature changes during operation. The system captures volume fluctuations as batteries "breathe" during charge-discharge cycles, providing insights into cell state-of-charge. Pressure sensors detect cell expansion and contraction patterns, while temperature sensors monitor thermal variations. Data is collected by advanced electronics with high-resolution processing capabilities and transmitted to battery management systems for real-time analysis and decision-making.

2What are the main benefits of using a battery monitoring system?

The primary benefits include enhanced safety through early detection of thermal irregularities, extended battery lifespan via optimized cell balancing, improved performance through precise state-of-charge monitoring, and reduced maintenance costs through predictive analytics. The system enables proactive identification of potential issues before they escalate, facilitates optimal charging strategies, and provides comprehensive data for informed maintenance decisions. Additionally, BaMoS supports compliance with industry safety standards and enables advanced battery management algorithms.

3How does a battery monitoring system extend battery lifespan?

BaMoS extends battery lifespan by monitoring pressure changes that indicate cell state-of-charge variations, enabling precise cell balancing to prevent overcharging and undercharging conditions. The system optimizes pressure levels, which can improve cycle lifetime by 30-40%. Temperature monitoring allows for proactive thermal management, preventing degradation from excessive heat or cold conditions. By maintaining uniform charging across all cells and preventing stress conditions, BaMoS maximizes the overall battery pack performance and longevity.

4How does a battery monitoring system improve battery safety?

BaMoS enhances safety through continuous monitoring of critical parameters that indicate potential hazards. Temperature sensors detect thermal runaway conditions before they escalate to dangerous levels, while pressure monitoring identifies cell swelling or gas generation that could indicate failure. The system provides early warning alerts for abnormal conditions, enabling preventive measures before safety incidents occur. Real-time data transmission allows for immediate response to critical situations, and comprehensive monitoring ensures compliance with safety protocols.

5How does a BMS optimize battery performance?

A Battery Management System optimizes performance by utilizing BaMoS data to implement intelligent charging algorithms, balance cell voltages, and manage thermal conditions. The system analyzes real-time pressure and temperature data to determine optimal charging rates and prevent stress conditions. Cell balancing capabilities ensure uniform energy distribution across the battery pack, maximizing capacity utilization. Performance optimization includes adaptive charging strategies based on environmental conditions and usage patterns, resulting in improved energy efficiency and extended operational range.

6What is State of Charge (SoC) and how does a BMS determine it?

State of Charge represents the current energy level of a battery expressed as a percentage of its maximum capacity. Our battery monitoring system determines SoC through multiple measurement techniques including voltage monitoring, current integration (coulomb counting), and innovative pressure sensing. Pressure changes during battery operation correlate with volume fluctuations that indicate charge levels. The system combines these measurements with advanced algorithms and historical data patterns to provide accurate SoC estimates. Machine learning capabilities enable continuous improvement of SoC accuracy through operational experience and environmental adaptation.