Contract manufacturing for printed electronics

FLEXOO delivers cost-effective contract manufacturing for printed electronics without compromising quality. Our ISO-certified production achieves proven customer savings of at least 10%, covering sensors, heaters, antennas, and flexible PCBs.

What is contract manufacturing?

Contract manufacturing is the outsourcing of production processes to specialized third-party manufacturers. In printed electronics, this means partnering with experts who handle everything from design optimization to mass production of electronic components like sensors, heating elements, antennas, and flexible PCBs using advanced printing technologies.

How does contract manufacturing work with FLEXOO?

You provide specifications that we transfer directly into production, or use our expertise for joint development projects. We optimize existing designs for function, cost, and quality. Our additive manufacturing minimizes process steps - applying ink and curing creates ready printed electronics in one efficient run.

Cost-efficient contract manufacturing from Germany

Manufacturing printed electronics without compromising quality or cost? At FLEXOO, we've cracked that code.

Proven results: Customers save at least 10%!

Why can FLEXOO manufacture printed electronics so cost-effectively?

- Highly automated roll-to-roll printing processes

- Top machining speed of 160 m/min with no downtime for product changes

- Unique worldwide machine specialization, 7 printing stages in one run

- Consolidated production steps

- Additive manufacturing saving material

You benefit directly from this enormous cost savings!

FLEXOO is an ISO-certified contract manufacturer

The machines in our ISO-certified production impress with quality and performance: more than 20 km of printed sensors, foil heaters, printed antennas or flexible PCBs are ready for shipment at the end of a shift.

Whether simple or highly complex, we execute your print order precisely according to your specifications. Our employees are recognized experts who learned their craft at world market leaders in the printing industry.

We supply renowned customers in demanding sectors such as automotive, medical technology, aerospace, and more.

From precise sensors to powerful antennas and flexible PCBs to efficient heating elements – our portfolio covers the entire range of modern printed electronics. You determine the specifications, we implement them.

Our contract manufacturing is extremely fast

We achieve this because we maximize a very decisive advantage of additive manufacturing, the low number of process steps. We produce multilayer electronics in just one run.

Applying the ink and curing – the printed electronics are ready.

1 million pieces of 2-layer 40x50 mm flexible PCBs in 8 hours

Other effective accelerators

- Machines and processes are networked. This applies from prototyping to setting up the production machine to quality monitoring. All steps are geared towards efficiency with consistently high quality.

- Access to process alternatives that optimize and shorten production time.

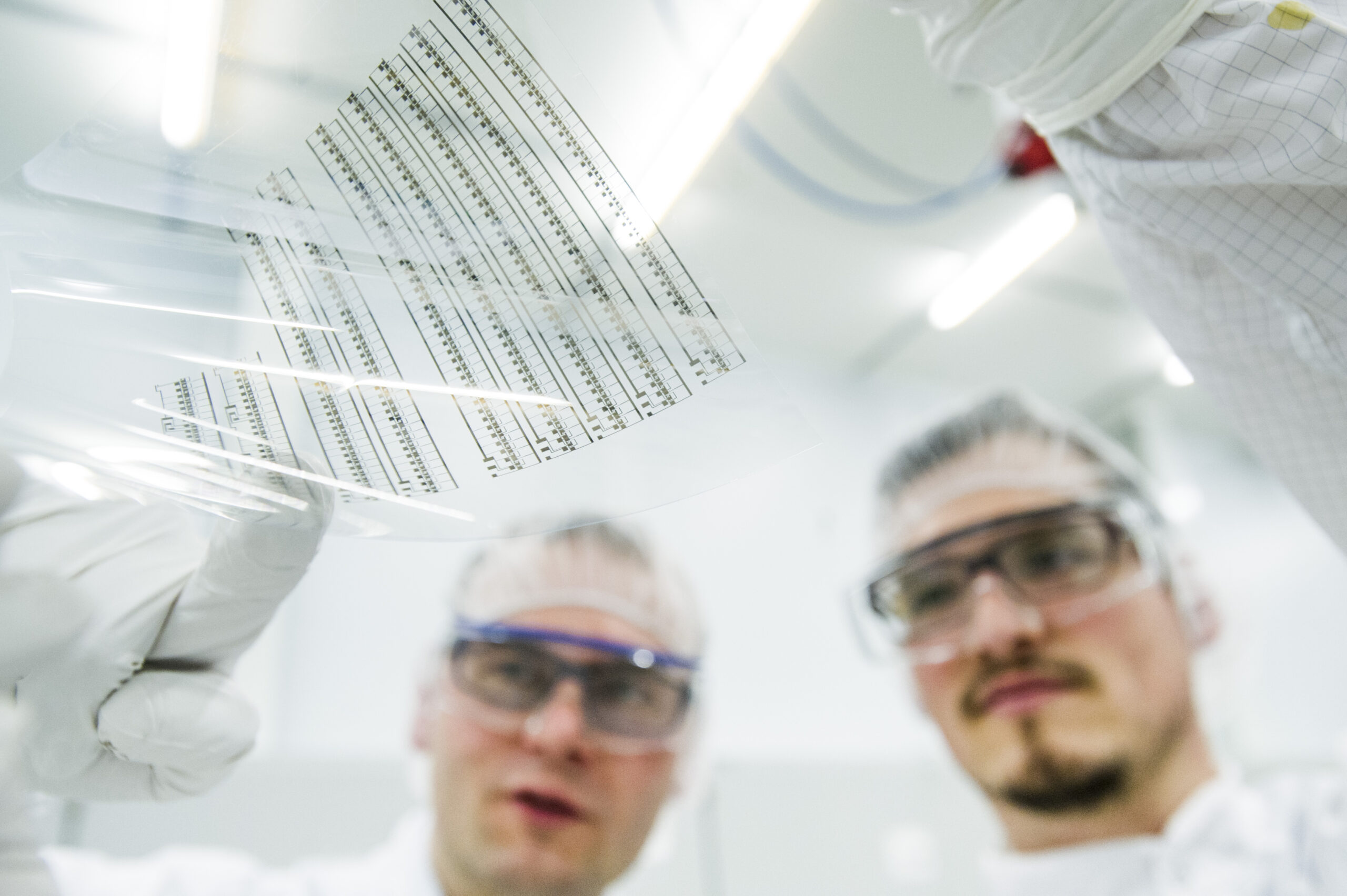

See manufacturing precision in action

Our production lines operate in ISO Class 7 cleanrooms, ensuring minimal contamination for high-quality electronic components. High-performance specialized lines offer maximum flexibility with 7 printing stages in one run and layer-to-layer accuracy up to <100 µm. Using rotary screen printing, flexographic printing, and slot die coating techniques, we achieve precise results with comprehensive finishing options including punching, die-cutting, and laminating.

Inks and substrates used in our contract manufacturing

We continuously push the boundaries of what is technically feasible in printed electronics. The following overview shows a selection of the materials we work with. Depending on project requirements, we develop customized solutions and also use unconventional materials if necessary. Our technology enables exceptional flexibility in combining different inks and substrates.

Inks (printing inks):

Metallic inks

- Gold (Au)

- Silver (Ag) and silver nanoparticles

- Solderable silver (Ag)

- Copper (Cu)

- Aluminum (Al)

- Nickel (Ni)

Carbon-based inks

- Carbon nanotubes (CNTs)

- Carbon black (C)

- Positive temperature coefficient (PTC)

Polymer-based organic inks

- PEDOT:PSS

- PVDF (Polyvinylidene fluoride)

- PVA (Polyvinyl alcohol)

- PVP (Poly-4-vinylphenol)

Substrates (carrier material):

Polymeter substrates

- Polyimide (PI)

- Polyethylene terephthalate (PET)

- Polyethylene naphthalate (PEN)

- Polycarbonate (PC)

Other substrates

- Paper (including Teslin paper)

- Textiles/fabrics

FLEXOO customizes your printed electronics

You have the choice: You either provide finished specifications that we transfer directly into production, or you use our expertise for joint development projects!

If desired, we optimize existing specifications in terms of function, cost, degree of integration, and quality level. Numerous market leaders already successfully use this service.

With us, you get design freedom without compromise. Additive processes allow the realization of complex geometric shapes that would not be manufacturable or only with considerable effort using conventional methods. This design freedom opens up new possibilities for your products. You benefit from higher individualization and thus unique advantages in competition.

The superpowers of our contract manufacturing

The superpowers of our production are the maximum performance values we achieve in categories important to you. The following selection provides a perfect orientation as to whether we are the perfect contract manufacturer for printed electronics for you. We think we most certainly are.

- Maximum machining speed: 160 m/min

- Minimum distance print lines: 50 µm

- Minimum width print lines: 50 µm

- Maximum print quality: fine line

- Maximum substrate width: 430 mm

- Maximum substrate length: no limitation

- Maximum substrate thickness: 500 µm

- Minimum substrate thickness: 2 µm

Why choose FLEXOO for contract manufacturing?

Frequently Asked Questions

Let’s start to work on your challenge!

Ready to take the next step? Reach out to our sales team today and discover how we can tailor our solutions to meet your needs.