Asset monitoring

Asset monitoring with FLEXOO's wireless sensors delivers real-time data for critical applications. Ultra-thin technology integrates seamlessly into existing systems for leakage detection, predictive maintenance, and inventory management.

What is asset monitoring?

Asset monitoring is the continuous tracking and analysis of physical assets using printed sensors and data collection systems. It provides real-time insights into asset condition, location, and performance through wireless technology, enabling proactive maintenance, inventory management, and operational efficiency improvements across industrial and logistics applications.

What problems does asset monitoring solve?

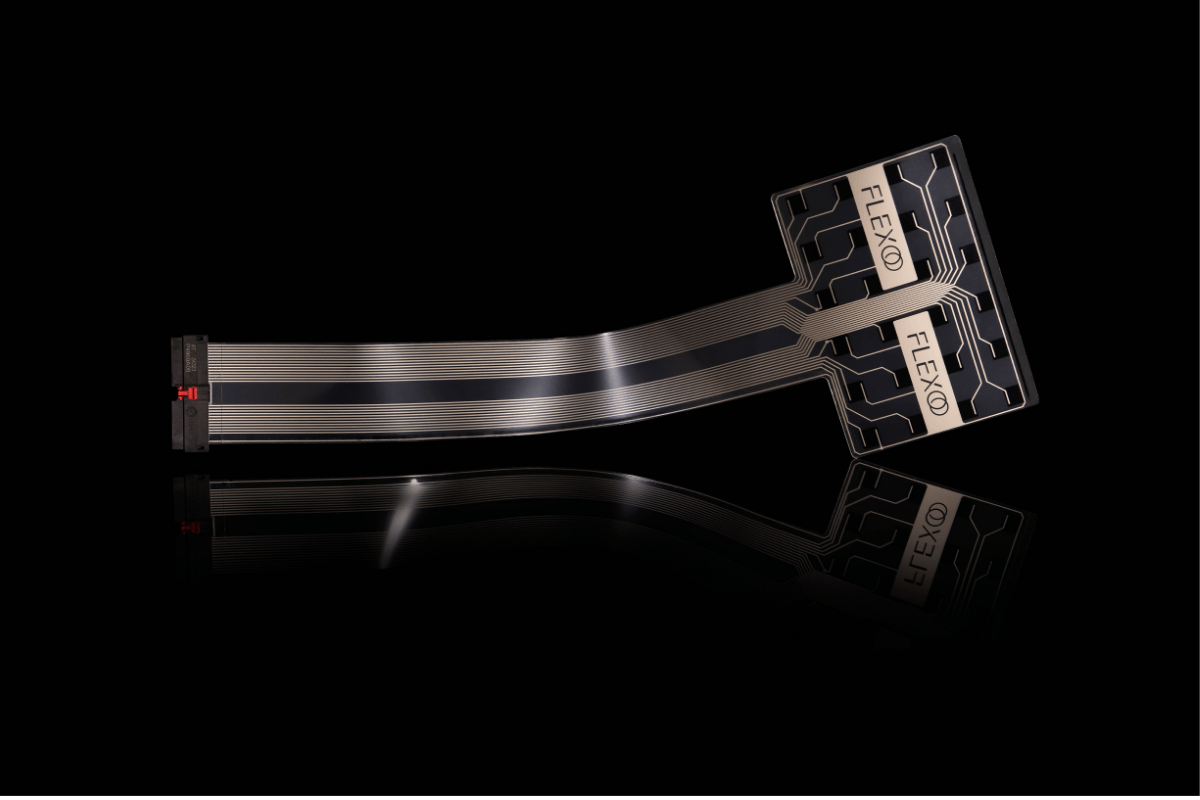

Flexible PCBs use ultra-thin, bendable substrates (such as polyimide) instead of rigid FR4. Copper traces are patterned onto this film, forming circuits that can bend, fold, or twist. They replace bulky wiring, save space, handle vibration, and reliably connect moving or tightly packed components in compact electronic designs.

Asset monitoring powered by MultiMoS wireless sensors

Our asset monitoring solutions leverage MultiMoS, FLEXOO's multi-parameter wireless sensor for real-time data collection in confined spaces.

MultiMoS delivers the world's most precise tactile sensing with superior signal quality, purpose-built for demanding asset monitoring applications.

Use case applications for asset monitoring

Industrial pipeline leak detection

Smart shelf occupancy detection

Equipment condition monitoring

Asset tracking in logistics operations

Why should you choose FLEXOO's asset monitoring solution?

Frequently Asked Questions

1. What types of assets can be monitored with FLEXOO's solution?

FLEXOO's wireless sensors can monitor various assets including industrial equipment, inventory items, pipelines, machinery, and mobile assets across logistics, manufacturing, and industrial environments.

2. Can the sensors withstand harsh industrial environments?

Yes, FLEXOO's wireless sensors operate reliably in temperature ranges from 10°C to 100°C and feature temperature drift compensation, making them suitable for demanding industrial conditions.

3. How is the sensor data collected and analyzed?

Data is collected wirelessly via Bluetooth and processed using MultiMoS software, which provides real-time analysis and export capabilities.

Let’s start to work on your challenge!

Ready to take the next step? Reach out to our sales team today and discover how we can tailor our solutions to meet your needs.

Contact our sales team!

Is your question more specific and would you like to talk to an expert? Make sure to reach out sales experts, they will be happy to advise you!