Applications for printed electronics

Explore how FLEXOO's printed electronics transform industries through intelligent applications. From automotive safety systems to medical devices and asset monitoring, our technology enables innovation across diverse sectors.

Printed electronics for battery energy storage systems (BESS) applications

BESS applications require reliable monitoring solutions to prevent thermal runaway and optimize performance. Cellular temperature sensors provide cellular-level measurement that detects pressure and temperature changes before critical conditions develop.

These ultra-thin in-situ sensors integrate even between battery cells without affecting pack and assembly design, enabling safer grid-scale energy storage installations. The technology supports the renewable energy transition through enhanced battery safety and extended operational lifespans.

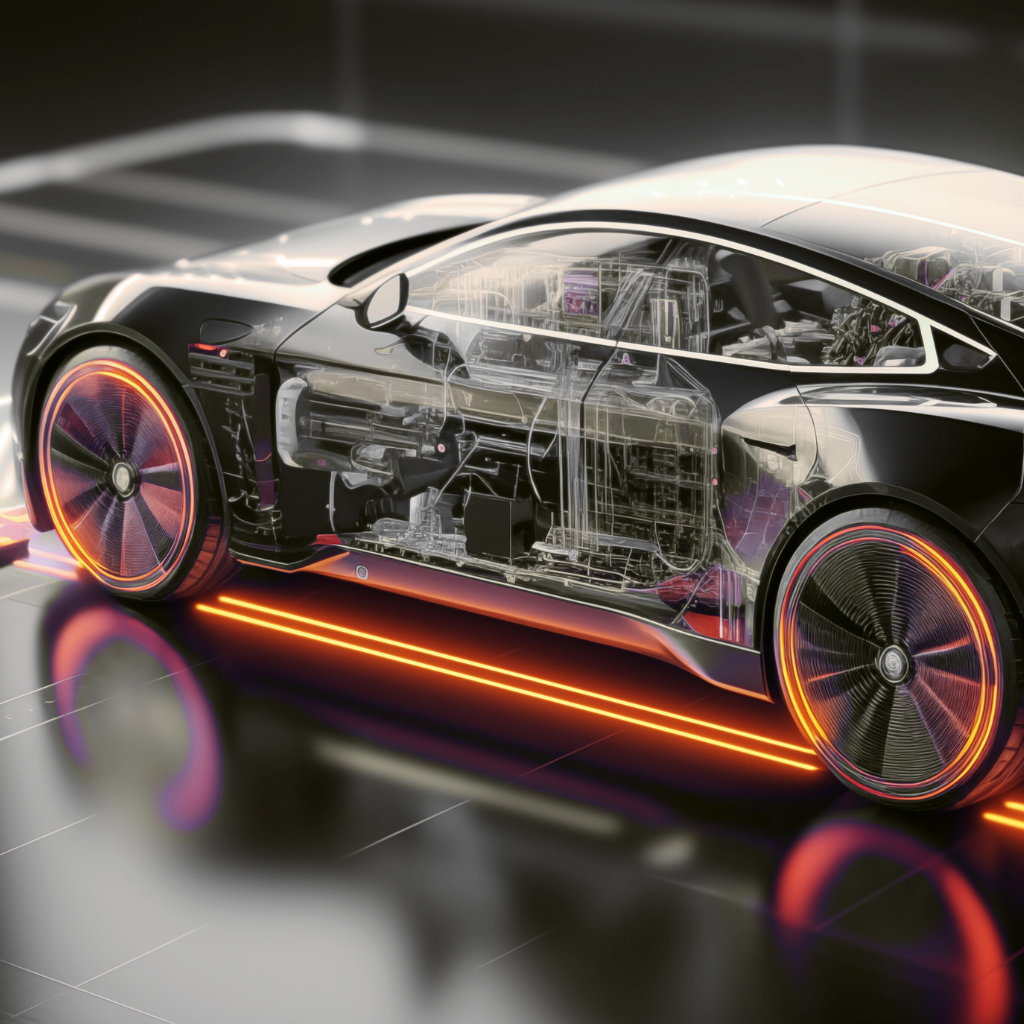

Printed electronics for automotive applications

Printed electronics enable advanced automotive solutions including battery monitoring systems for electric vehicles, flexible heating elements for de-icing systems and more occupant comfort, and printed sensors for safety applications.

Ultra-thin sensors integrate seamlessly into vehicle architectures while delivering critical measurements that enable higher-level control systems to respond more individually, quickly, and precisely. These solutions support the automotive industry's transition to electrification and digitalization with reliable, space-efficient components that enhance vehicle performance and safety.

Printed electronics for medtech applications

Medical applications benefit from printed electronics through flexible sensors for patient monitoring, ultra-thin heating elements for therapeutic devices, and specialized sensors for ostomy care that enhance comfort and quality of life.

The technology enables continuous health monitoring through wearable devices that conform to body movements while maintaining functionality. Printed electronics provide medical device manufacturers with cost-effective solutions for remote patient monitoring and personalized healthcare applications.

Printed electronics for IoT and smart building applications

Internet of Things applications leverage printed electronics for distributed sensing networks, printed antennas, and energy-efficient monitoring systems. Smart buildings benefit from large-area sensors that monitor occupancy, environmental conditions, and structural health across extensive surfaces.

These solutions enable intelligent building management through real-time data collection while reducing installation complexity and maintenance requirements compared to traditional sensor networks.

Printed electronics for aerospace applications

Aerospace applications demand lightweight, reliable printed electronics for weight-critical systems including aircraft heating elements, sensor networks, and communication antennas. Ultra-thin foil heaters prevent ice formation on critical surfaces while adding minimal weight to aircraft designs.

Printed sensors enable real-time monitoring of structural health and environmental conditions in challenging aerospace environments where traditional electronics would be impractical or too heavy.

Printed electronics for industrial monitoring applications

Industrial environments benefit from printed electronics through asset monitoring systems, leak detection sensors, and predictive maintenance solutions.

Wireless sensors enable monitoring in inaccessible locations while providing real-time data for operational optimization. These applications include pipeline monitoring, equipment health tracking, and inventory management systems that reduce operational costs through early problem detection and automated data collection processes.

Printed electronics for wearable technology applications

Wearable applications utilize printed electronics for fitness monitoring, health tracking, and smart textile integration. Flexible circuits conform to clothing and body movements while maintaining electrical functionality for continuous monitoring.

These applications enable seamless integration of electronics into garments, medical devices, and accessories without compromising comfort or durability. The technology supports next-generation wearables with enhanced user experience and functionality.

Let’s start to work on your challenge!

Ready to take the next step? Reach out to our sales team today and discover how we can tailor our solutions to meet your needs.

Contact our sales team!

Is your question more specific and would you like to talk to an expert? Make sure to reach out sales experts, they will be happy to advise you!