Flex PCBs

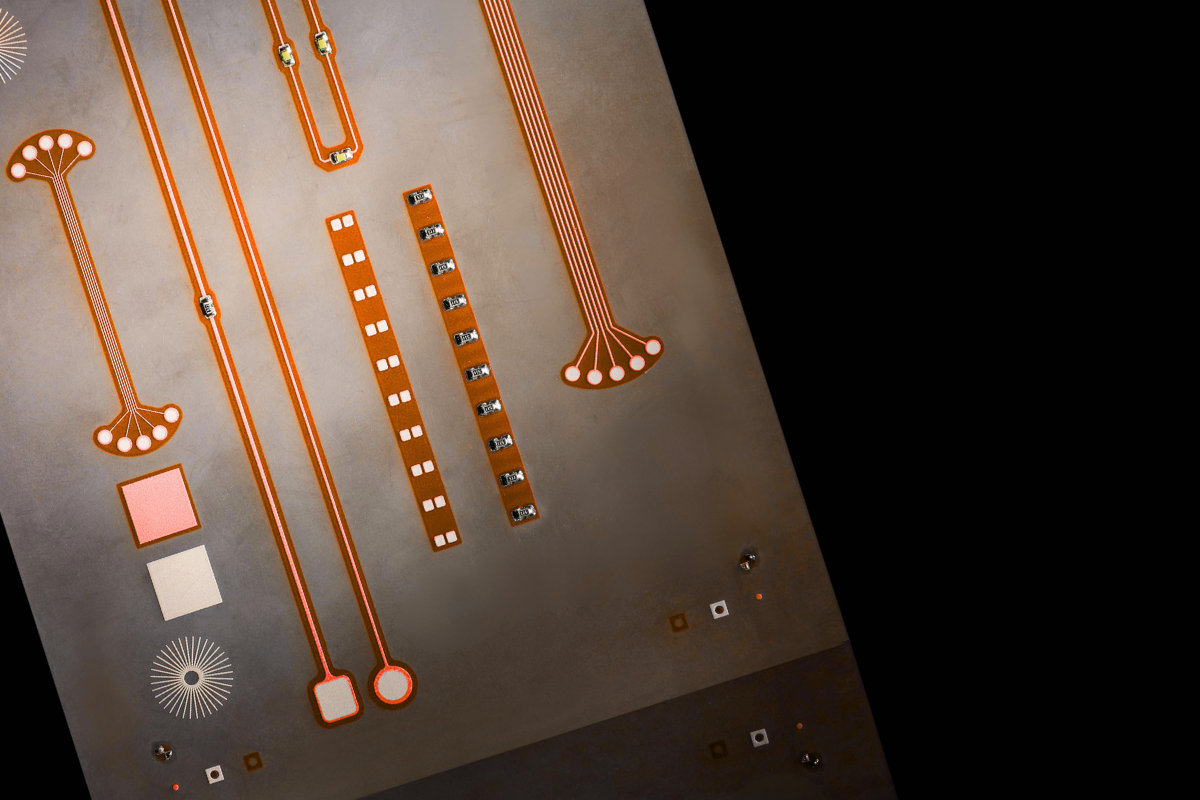

FLEXOO delivers innovative Flex PCB solutions with a game-changing advantage: 100% solderable flexible circuits. As one of the few suppliers, we master the technology of manufacturing solderable flexible PCBs that eliminate the need for expensive connection methods.

We manufacture three key Flex PCB types: Single-sided circuits perfect for cost-sensitive applications like RFID tags, multi-layer designs up to 2 layers for complex functionality, and specialized wearable PCBs that seamlessly integrate into clothing and medical devices.

What are Flex PCBs?

Flexible printed circuit boards (Flex PCBs) are a groundbreaking type of electronic circuit designed to bend, twist, and fold without losing electrical performance, unlike traditional rigid boards. Made with materials like polyimide, they allow copper traces to carry signals even when flexed. This inherent flexibility enables them to fit into unique shapes and tight spaces, revolutionizing product design where rigid boards simply won't work.

How do Flex PCBs work?

Flexible PCBs use ultra-thin, bendable substrates (such as polyimide) instead of rigid FR4. Copper traces are patterned onto this film, forming circuits that can bend, fold, or twist. They replace bulky wiring, save space, handle vibration, and reliably connect moving or tightly packed components in compact electronic designs.

Why should you choose FLEXOO as your Flex PCB provider?

Use case applications for Flex PCBs

Flex PCBs in MedTech

Flex PCBs in the automotive industry

Flex PCBs in IoT and wearables

Flex PCBs in smart packaging

Frequently Asked Questions

1. How long do Flex PCBs last compared to rigid ones?

The lifespan of Flex PCBs and rigid PCBs depends heavily on the respective operating conditions, material quality and design. Flex PCBs are designed to withstand repeated bending and movements, often providing higher durability than rigid circuit boards in dynamic applications. With optimal design and under suitable operating conditions, Flex PCBs can achieve comparable or even longer lifespans than rigid PCBs. Decisive factors include temperature, humidity, vibrations and the quality of materials used.

2. Can I convert my existing PCB design?

In most cases, it's possible to transfer an existing circuit board design to a flexible PCB. Of course, some important aspects must be considered, including: selection of suitable materials, bending radius, placement and mounting of components, specific design rules for flexible circuits.

3. How do you handle component assembly on flexible PCBs? Can you use standard SMD production lines?

Yes, our flexible PCBs are fully compatible with standard Surface Mount Technology (SMT) assembly processes. We use reflow-solderable inks that enable seamless integration with your existing automated SMD production lines.

4. How thin can FLEXOO Flex PCBs be manufactured?

We print on ultra-thin, flexible substrates that maintain functionality even when bent or flexed repeatedly. The exact thickness depends on your specific application requirements.

5. What materials do you use for Flex PCBs?

Currently, the most popular materials for FLEXOO's Flex PCBs are: silver, dopper, carbon-based inks - used especially for contact protection, dielectric, solder mask; substrate made of PI, PET, PEN, FR4. Different ink? Different substrate? No problem! We're happy to expand the possibilities of flexible PCBs. Tell us your ideas and we'll examine feasibility for optimal results.

Let’s start to work on your challenge!

Ready to take the next step? Reach out to our sales team today and discover how we can tailor our solutions to meet your needs.

Contact our sales team!

Is your question more specific and would you like to talk to an expert? Make sure to reach out sales experts, they will be happy to advise you!