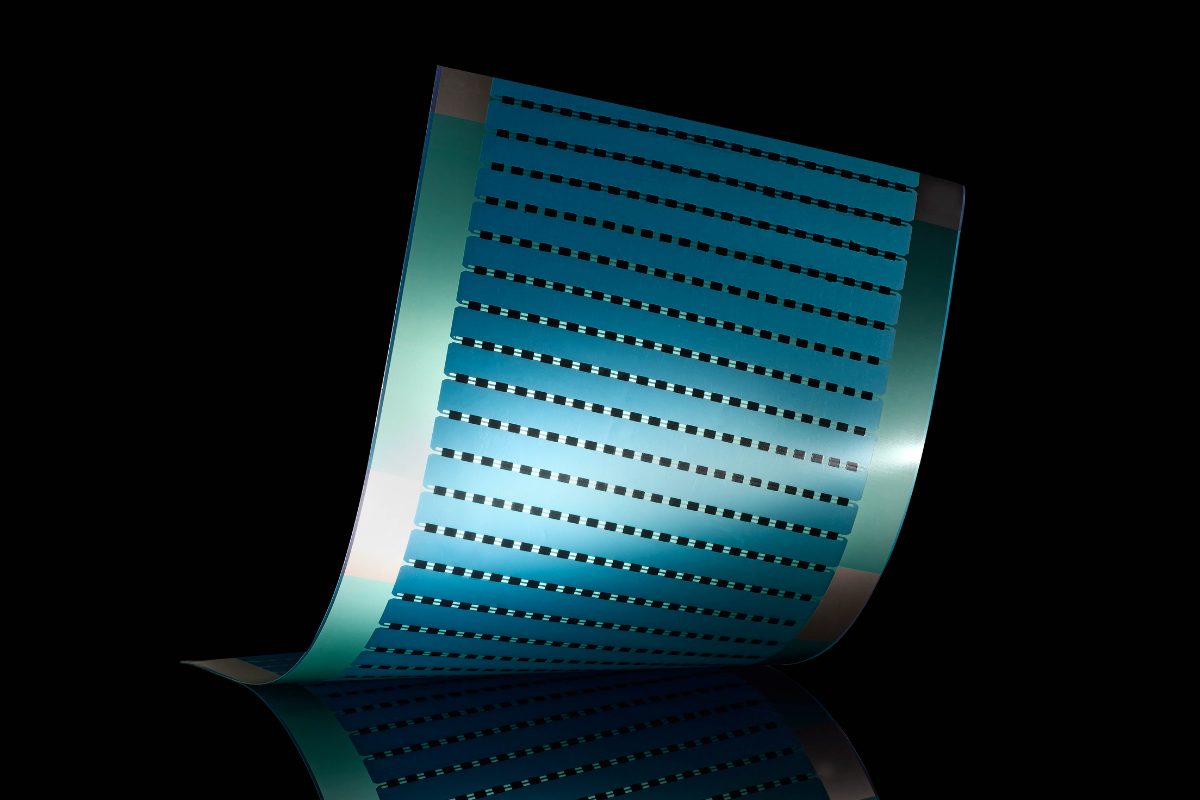

Foil heaters

When standard heating solutions don't fit, FLEXOO's printed heating elements adapt. Our flexible foil heaters conform to complex geometries where rigid heaters fail, delivering efficient heat distribution exactly where needed.

What are foil heaters?

Foil heaters are printed functional elements on flexible substrates using conventional printing processes. Built on thin polyester or polyimide films with embedded conductive elements, they heat up when voltage is applied. FLEXOO provides self-regulating PTC heaters or fixed power variants for different applications.

What problems do foil heaters solve?

Traditional heating systems add unnecessary bulk and weight to applications. Foil heaters eliminate space constraints, reduce assembly complexity, and provide uniform heat distribution across complex geometries. They prevent overheating through self-regulation and deliver heat faster where it should be while consuming less energy.

Why should you choose FLEXOO as your flexible foil heater provider?

Use case applications for foil heaters

Foil heaters in automotive

Foil heaters in medical devices

Foil heaters in textiles

Foil heaters in aerospace

Frequently Asked Questions

1. What are the typical thickness limitations for foil heaters?

FLEXOO's printed heating elements are produced on very thin and flexible substrates. Substrate thickness typically varies between some microns to some hundred microns. The ultra-thin design allows heaters to be placed directly below covers, enabling faster heat transfer and reduced energy consumption compared to traditional heating systems.

2. Can foil heaters be made in complex shapes or with cutouts?

Yes, manufacturing by printing processes allows high freedom of form factor. FLEXOO's heating elements can be printed in any format without compromises in device design. The additive printing process enables custom shapes, complex geometries, and integration of multiple functions like sensors within the same element.

3. How are foil heaters installed or integrated? What connection options are available?

FLEXOO's foil heaters offer direct integration into existing designs with reduced assembly complexity. Installation methods include adhesive mounting, mechanical fastening, and direct integration during manufacturing processes.

4. What is the typical lead time for foil heater orders? How long does it take from the initial request for quotation to series production?

FLEXOO's state-of-the-art, ISO-certified production provides cost-effective, customized solutions. Even with large quantities, FLEXOO ensures high delivery reliability. Our fully automated mass production processes enable efficient scaling from prototypes to series production, though specific lead times depend on complexity and volume requirements.

5. Do you offer technical support for foil heater integration?

Yes, FLEXOO provides comprehensive technical support throughout the entire process. Our expertise covers design consultation, material selection, integration assistance, and ongoing support during production. We help optimize heater designs for specific application requirements and provide guidance for successful implementation across various industries.

Let’s start to work on your challenge!

Ready to take the next step? Reach out to our sales team today and discover how we can tailor our solutions to meet your needs.

Contact our sales team!

Is your question more specific and would you like to talk to an expert? Make sure to reach out sales experts, they will be happy to advise you!