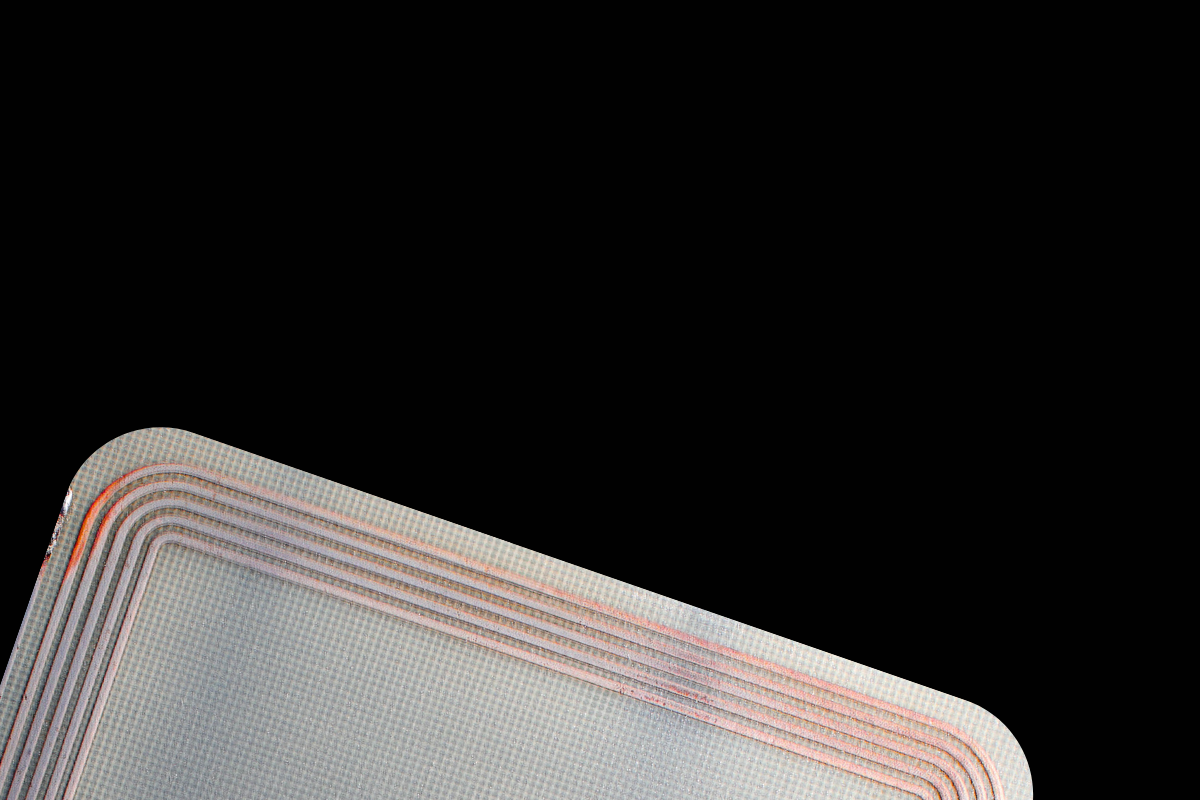

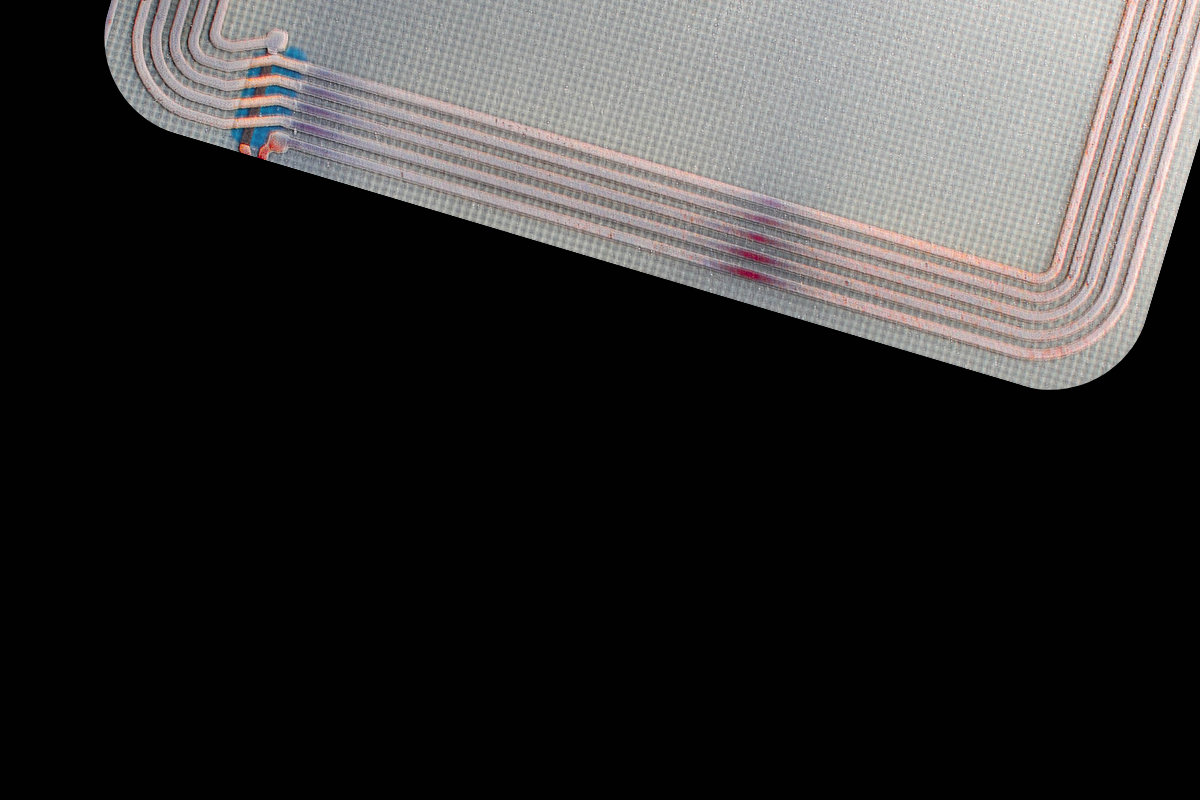

Printed antennas

Printed antennas enable compact, lightweight wireless communication solutions for modern electronics. These cost-effective components integrate seamlessly into IoT devices, wearables, and smart systems.

What are printed antennas?

Printed antennas are thin, flexible wireless communication components manufactured using printing techniques on various substrates. Unlike traditional antennas, they can be produced as flat, lightweight structures that conform to curved surfaces and integrate directly into electronic devices, making them ideal for space-constrained applications.

What problems do printed antennas solve?

Printed antennas address key challenges in modern electronics: space limitations in compact devices, high manufacturing costs of traditional antennas, integration difficulties in curved or flexible products, and the need for customized designs. They enable wireless connectivity in IoT sensors, wearables, and smart packaging where conventional antennas cannot fit.

Why should you choose FLEXOO as your printed antenna provider?

Use case applications for printed antennas

Printed antennas for IoT sensor networks

Printed antennas in wearable devices

Printed antennas for automotive connectivity

Printed antennas for smart packaging and RFID

Frequently Asked Questions

Let’s start to work on your challenge!

Ready to take the next step? Reach out to our sales team today and discover how we can tailor our solutions to meet your needs.

Contact our sales team!

Is your question more specific and would you like to talk to an expert? Make sure to reach out sales experts, they will be happy to advise you!