Large-area sensors

There is no point in only single point sensing! FLEXOO's large-area sensing devices make surfaces smart by providing sensitivity to pressure, temperature, and humidity across extensive areas with real-time data acquisition.

What are large-area sensors?

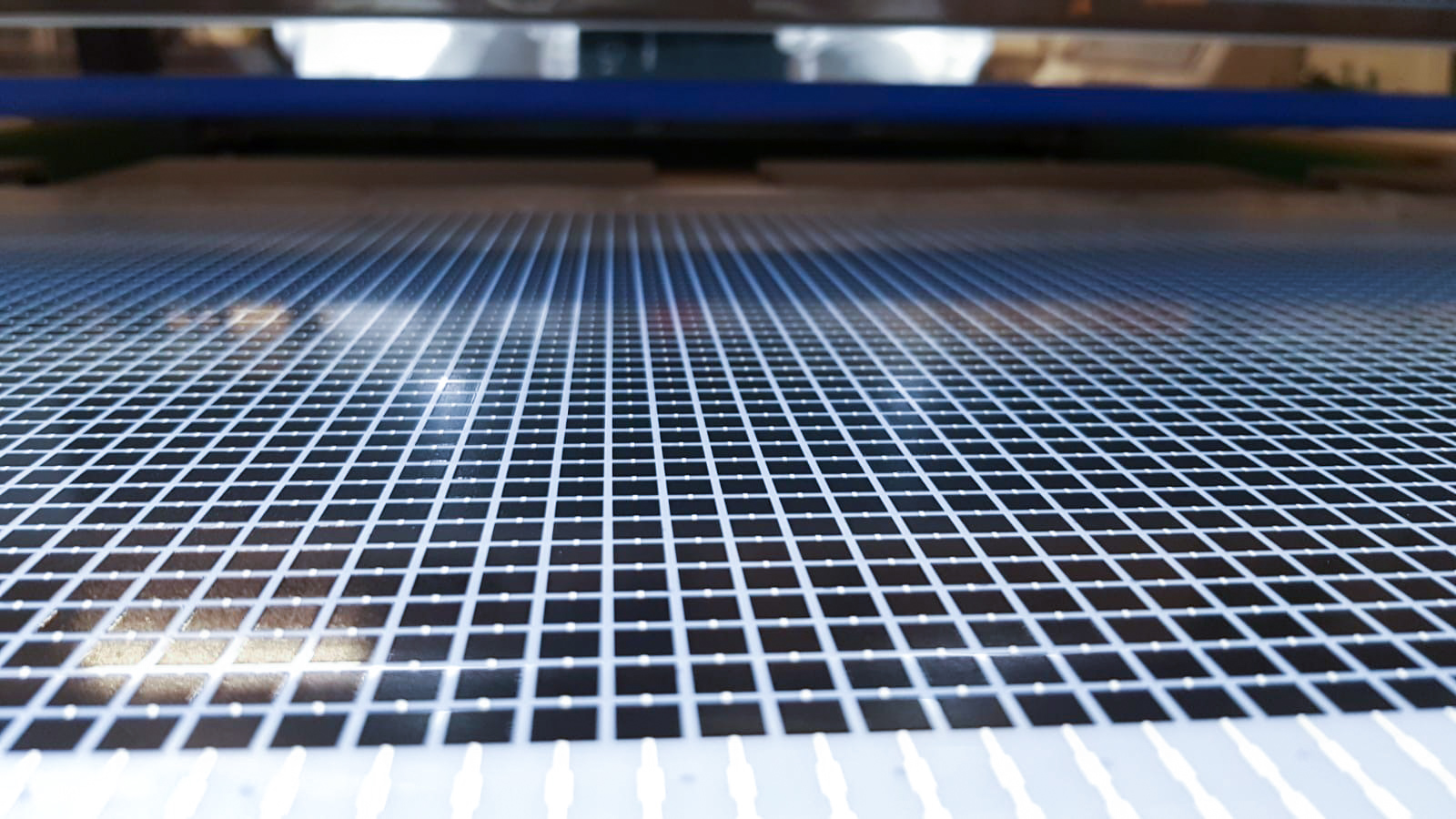

Large-area sensors are printed sensing matrices that cover extensive surfaces to provide distributed measurement capabilities. Unlike traditional point sensors, they offer continuous monitoring across tens of meters without additional connectors. Our patented technology combines temperature and pressure mapping in one device with integrated readout and visualization.

What problems do large-area sensors solve?

Traditional sensors provide limited spatial information from single measurement points. Large-area sensors eliminate blind spots by offering comprehensive coverage, reduce system complexity through integrated electronics, and provide real-time mapping of physical parameters. They enable predictive maintenance and safety monitoring where conventional sensors fail.

Why should you choose FLEXOO as your large-area sensor provider?

Use case applications for large-area sensors

Frequently Asked Questions

Let’s start to work on your challenge!

Ready to take the next step? Reach out to our sales team today and discover how we can tailor our solutions to meet your needs.

Contact our sales team!

Is your question more specific and would you like to talk to an expert? Make sure to reach out sales experts, they will be happy to advise you!